How Artificial Intelligence is Revolutionizing Supply and Chain Management?

What are the Key Challenges in Traditional Supply Chain Management?

In today’s competitive global market, supply and chain management plays a vital role in ensuring that goods and services reach customers efficiently. However, traditional systems often face several obstacles that can disrupt operations, increase costs, and lower customer satisfaction. Below are the major challenges commonly encountered.

Demand Forecasting Inaccuracies

One of the most persistent issues is inaccurate demand forecasting. Relying on historical data without factoring in market trends, seasonal changes, or unexpected disruptions can lead to either stockouts or overstocking. Both scenarios negatively affect sales and profitability. Effective chain management requires advanced tools that can process real-time data and predictive analytics to improve accuracy.

Inventory Mismanagement

Traditional supply chains often struggle with poor inventory control. Without a clear view of what’s in stock, businesses may either run out of key products or tie up capital in unsold goods. Manual inventory tracking or outdated software contributes to errors and inefficiencies. Automating inventory management and integrating it with other systems can enhance responsiveness and reduce waste.

Supplier and Logistics Delays

Delays in receiving materials from suppliers or shipping finished products to customers can seriously impact timelines. These delays may be due to poor coordination, geopolitical factors, or lack of communication between stakeholders. Building strong relationships with suppliers and using real-time tracking can help mitigate these risks.

Lack of Real-Time Visibility and Data Integration

One of the most critical limitations is the absence of real-time visibility across the supply chain. Disconnected systems and siloed data prevent timely decision-making. For modern businesses, integrating data from suppliers, warehouses, and logistics providers into a unified platform is essential for agility and performance.

What is the Role of Artificial Intelligence in Supply Chain Management?

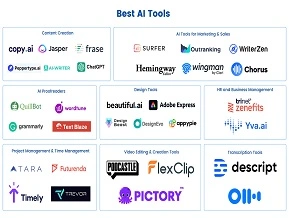

In recent years, artificial intelligence (AI) has become a transformative force in supply chain management, helping businesses overcome traditional challenges and gain a competitive edge. From intelligent forecasting to automated decision-making, AI technologies are reshaping how supply chains operate.

AI Technologies in Action

AI-powered tools such as machine learning (ML), natural language processing (NLP), and computer vision are widely applied across supply chains. ML models can identify patterns in historical data to improve demand forecasting. NLP enables systems to interpret and respond to natural language queries, streamlining communication between systems and personnel. Meanwhile, computer vision is used in quality control, warehouse management, and tracking shipments through image recognition.

Real-Time Data Processing and Analytics

AI excels at processing vast amounts of data in real time. This capability allows supply chain managers to make informed decisions quickly, especially during disruptions or sudden changes in demand. Predictive analytics powered by AI can forecast delays, identify bottlenecks, and suggest optimal shipping routes, thereby improving efficiency and customer satisfaction.

Automation of Repetitive Tasks

AI automates many of the repetitive and time-consuming tasks in this, such as order processing, inventory updates, and shipment tracking. Robotic Process Automation (RPA), often driven by AI algorithms, reduces manual errors and frees up human workers for more strategic roles. Automation also improves consistency and speed across operations.

By leveraging cutting-edge technologies, companies can enhance accuracy, speed, and adaptability throughout their supply chain networks. As AI continues to evolve, its role in driving smarter, more resilient supply chains will only grow stronger.

How is AI Transforming Forecasting and Inventory Optimization in Supply Chain Management?

Artificial intelligence is playing a key role in transforming this, especially in the areas of demand forecasting and inventory optimization. By leveraging AI-powered tools, businesses can make smarter decisions, reduce costs, and ensure product availability.

Predictive Analytics for Accurate Demand Forecasting

Traditional forecasting methods often rely on historical data alone, leading to inaccurate projections. AI, particularly through predictive analytics, enables companies to analyse large and diverse datasets—including market trends, seasonal patterns, and real-time sales activity—to forecast demand with much greater precision.

Dynamic Inventory Management and Smart Restocking

AI-driven systems allow for real-time inventory tracking and intelligent restocking decisions. Instead of relying on fixed reorder points, smart algorithms continuously monitor stock levels, customer demand, and supplier performance to dynamically adjust inventory thresholds. This ensures that businesses maintain optimal stock levels, preventing both stockouts and excessive inventory build-up.

Reducing Waste and Overstock

One of the most significant benefits of AI in inventory management is its ability to reduce waste and overstock. Overstocking ties up capital and increases storage costs, while understocking results in lost sales. AI systems help strike the right balance by forecasting precise quantities and optimizing order cycles. Additionally, AI can analyse product life cycles and expiration dates, particularly useful in industries like food and healthcare, to minimize spoilage and obsolescence.

Businesses that embrace these technologies can respond more effectively to market changes, reduce operational inefficiencies, and better serve their customers through accurate, timely product availability.

How is AI Enhancing Logistics and Delivery in Supply and Chain Management?

Artificial intelligence is significantly enhancing the logistics and delivery components of supply and chain management, enabling businesses to achieve faster, more efficient, and cost-effective operations. From smart routing to autonomous deliveries, AI is reshaping how goods move from warehouses to customers.

AI for Route Optimization and Delivery Tracking

AI algorithms can analyse vast amounts of data to determine the most efficient delivery routes. By factoring in variables like distance, delivery windows, traffic conditions, and fuel consumption, AI helps optimize logistics routes in real time. This leads to reduced delivery times, lower operational costs, and improved customer satisfaction. Additionally, AI-powered tracking systems provide real-time updates, allowing businesses and customers to monitor shipments every step of the way.

Autonomous Vehicles and Drones

AI is driving innovation in autonomous transportation. Self-driving delivery trucks and drones are being tested and implemented by forward-thinking companies to reduce human dependency and speed up last-mile deliveries. These autonomous systems use AI for obstacle detection, navigation, and dynamic path adjustments, ensuring safe and timely delivery. They are particularly useful in remote or high-demand urban areas where traditional logistics face challenges.

Real-Time Traffic and Weather-Based Decision-Making

AI systems also integrate real-time traffic and weather data into logistics planning. For instance, if a sudden storm or traffic jam is detected, the system can instantly reroute the delivery vehicle to avoid delays. This level of adaptability is critical for maintaining reliability and meeting customer expectations, especially during peak seasons or emergencies.

These advancements not only improve operational efficiency but also set new standards for speed and customer service in modern supply chains.

How is AI Powering Supplier Management and Risk Mitigation in Supply Chain Management?

Artificial intelligence is revolutionizing supply chain management by improving how businesses manage suppliers and mitigate risks. With AI tools, companies can evaluate supplier performance, predict potential disruptions, and create more resilient and responsive supply chains.

Evaluating Supplier Performance with AI

Traditional methods of supplier evaluation often rely on manual reviews and outdated performance metrics. AI changes this by continuously monitoring key performance indicators such as delivery times, quality standards, compliance history, and cost efficiency. Machine learning models can process this data at scale, offering real-time insights into which suppliers are performing well and which may need to be replaced or supported with corrective actions.

Identifying and Predicting Supply Disruptions

One of the most powerful applications of AI in supplier management is the ability to anticipate disruptions before they occur. By analysing historical data, current events, and external variables—such as geopolitical issues, natural disasters, or financial instability—AI can alert companies to potential threats to their supply chain. This allows businesses to act proactively rather than reactively, minimizing downtime and maintaining continuity.

Risk Scoring and Contingency Planning

AI tools can assign risk scores to each supplier based on a range of factors including reliability, geographic location, and past incident history. These scores help prioritize which suppliers pose the most risk to operations. Businesses can then develop tailored contingency plans, such as diversifying their supplier base or securing backup inventory, to prepare for potential issues.

In summary, AI enhances this by bringing intelligence, speed, and foresight to supplier evaluation and risk mitigation. As global supply chains grow more complex, the ability to monitor and respond to risks in real time will be essential for building resilient and competitive operations.

What are the Considerations in Adopting AI for Supply Chain Management?

While artificial intelligence offers significant benefits, its adoption in supply chain management also presents several challenges and considerations. From technical limitations to human factors, businesses must carefully navigate these hurdles to implement AI successfully and sustainably.

Integration with Existing Systems

One of the main challenges is integrating AI technologies with legacy systems. Many companies rely on outdated infrastructure that is not built to support modern AI tools. As a result, implementation may require costly upgrades, custom interfaces, or complete system overhauls. Seamless integration is crucial to ensure data flows efficiently between platforms and departments, allowing AI to generate meaningful insights.

Data Privacy and Security Concerns

AI in this relies heavily on large volumes of data, much of which may be sensitive or proprietary. Ensuring the privacy and security of this data is essential, especially when dealing with suppliers, customers, and third-party platforms. Companies must invest in secure data storage, encrypted communication channels, and robust cybersecurity practices to protect against breaches and ensure compliance with data protection regulations.

Skills and Training Gaps

Another key consideration is the skills gap. Implementing AI requires specialized knowledge in data science, machine learning, and supply chain operations. Many organizations lack the internal expertise needed to develop, maintain, and interpret AI systems. Closing this gap involves investing in training programs for existing staff or hiring new talent with the necessary technical skills.

While the adoption of AI in this holds transformative potential, organizations must address these critical challenges. By planning ahead for system integration, prioritizing data security, and developing a skilled workforce, businesses can harness the full power of AI while avoiding common pitfalls.

What is the Future of AI in Supply and Chain Management?

The future of supply and chain management is being rapidly reshaped by emerging AI technologies that promise to make supply chains smarter, faster, and more resilient. As digital transformation continues, businesses are exploring advanced tools such as generative AI, digital twins, and blockchain to optimize operations and drive innovation.

Emerging Trends: Generative AI, Digital Twins, Blockchain Integration

Generative AI is becoming a powerful tool in scenario planning and decision support. It can simulate supply chain responses to various disruptions, helping managers plan more effectively. Digital twins—virtual replicas of physical supply chain networks—allow real-time monitoring and testing of strategies before real-world implementation. Blockchain integration is also gaining traction, offering secure, transparent, and tamper-proof data sharing between suppliers, manufacturers, and distributors.

The Shift Toward Autonomous, Self-Healing Supply Chains

AI is paving the way for autonomous supply chains that can self-correct in response to disruptions. These self-healing systems use AI to detect issues such as delays, shortages, or quality concerns and automatically reroute orders, adjust production schedules, or find alternative suppliers. This reduces downtime, increases agility, and ensures continuous delivery, even in volatile environments.

Ethical and Sustainable AI Use in Global Supply Chains

As AI adoption grows, so does the need for ethical and sustainable practices. Companies must ensure that AI is used responsibly, without reinforcing bias or compromising worker rights. Additionally, AI can support sustainability by optimizing routes to reduce carbon emissions, minimizing waste, and improving resource efficiency.

AI is set to redefine the future of this. By embracing emerging technologies and prioritizing ethical use, businesses can create more intelligent, resilient, and sustainable supply chains for the global economy.

Conclusion

Artificial intelligence is transforming both supply and chain management and supply chain management, offering powerful tools for accurate forecasting, efficient logistics, real-time decision-making, and proactive risk management. As global supply chains grow more complex, the need for intelligent, automated, and data-driven solutions becomes essential. Embracing AI not only boosts efficiency but also builds resilience and sustainability across operations. To stay ahead in this evolving landscape, professionals should actively explore AI tools and upskill through targeted training. LAI’s AI courses for supply chain professionals provide the knowledge and practical skills needed to lead innovation in the field.