How Artificial Intelligence in Industries is Driving Productivity and Profitability?

What is Artificial Intelligence in Industries?

Artificial Intelligence (AI) in industries refers to the use of AI technologies to automate, optimize, and enhance various industrial processes. From manufacturing to supply chain management, AI is transforming how industries operate, offering improved efficiency, safety, and productivity.

Understanding Industrial AI

Industrial AI involves the integration of AI tools like machine learning, robotics, and data analytics into industrial settings. Unlike consumer-focused AI (e.g., virtual assistants), industrial AI is tailored to handle complex, large-scale operations in sectors such as manufacturing, energy, logistics, and construction. These systems help monitor machinery, predict failures, manage resources, and support decision-making with minimal human intervention.

Industrial AI vs. General AI Applications

While general AI is designed to perform a wide range of tasks that mimic human intelligence, industrial AI focuses on specific applications that enhance operational performance. For example, general AI may power chatbots or language models, but industrial AI might optimize assembly line production or forecast equipment maintenance needs. The key difference lies in specialization and context—industrial AI is purpose-built for solving industry-specific challenges.

Key Technologies Behind AI in Industries

Several cutting-edge technologies power AI in industrial settings:

- Machine Learning (ML): Enables systems to learn from historical data and improve over time without explicit programming.

- Robotics: Automates physical tasks, from assembly to inspection, reducing the need for manual labour.

- Internet of Things (IoT): Connects machines and sensors to collect and transmit real-time data for monitoring and analysis.

- Predictive Analytics: Uses data and AI algorithms to forecast equipment failures, optimize processes, and reduce downtime.

These technologies work together to create smarter, more responsive industrial systems. AI in industries is revolutionizing traditional operations by leveraging data-driven insights and automation to drive growth, reduce costs, and improve overall performance.

How is AI Transforming Core Operations in Industries?

Industries is driving a fundamental shift in how core operations are managed, optimized, and executed. By combining intelligent automation with data-driven insights, industries are unlocking new levels of efficiency and innovation.

Automating Repetitive and Manual Tasks

One of the most significant impacts of AI in industrial settings is the automation of repetitive and time-consuming tasks. Traditionally, many industrial processes relied heavily on manual labour, which often resulted in inefficiencies, higher costs, and safety risks. With AI-powered systems, tasks such as data entry, quality checks, and material handling can now be performed faster, more accurately, and with minimal human intervention. This not only reduces labour costs but also allows workers to focus on higher-value tasks.

Smart Robotics in Manufacturing and Logistics

Smart robotics is another transformative force within industrial environments. Integrated with AI, robots are no longer limited to rigid, pre-programmed actions—they can now adapt to changes, learn from experience, and work safely alongside humans. In manufacturing, robots assemble complex components with precision and speed. In logistics, autonomous robots and vehicles streamline warehouse operations, manage inventory, and accelerate order fulfilment processes.

Real-Time Monitoring and Predictive Maintenance

AI systems equipped with sensors and analytics tools enable real-time monitoring of equipment and processes. This continuous data collection helps identify anomalies before they become critical issues. Predictive maintenance, powered by machine learning, allows businesses to anticipate equipment failures and perform timely interventions. This reduces downtime, extends machinery life, and minimizes production disruptions. Industries is reshaping the industrial landscape by making operations smarter, faster, and more resilient. As AI technologies continue to evolve, industries that embrace them will be better positioned to lead in a competitive, technology-driven world.

How is Artificial Intelligence in Industries Boosting Productivity?

It is proving to be a powerful catalyst for boosting productivity and driving operational excellence. By automating complex processes, enhancing decision-making, and improving supply chain visibility, AI is helping businesses achieve more with less.

Reducing Downtime and Enhancing Efficiency

Downtime is one of the most costly issues in industrial operations. AI helps reduce it through predictive maintenance and intelligent monitoring. By analysing real-time data from machines and equipment, AI systems can detect early signs of wear or malfunction, allowing teams to schedule maintenance before a breakdown occurs. This proactive approach minimizes unexpected downtime, ensures smoother operations, and increases equipment lifespan—all of which contribute to higher overall efficiency.

Optimizing Supply Chain and Inventory Management

AI is transforming supply chain and inventory management by providing accurate demand forecasting, automating reordering processes, and offering real-time tracking of goods. With machine learning algorithms, businesses can analyse historical sales data, market trends, and external factors to predict future demand more precisely. This results in optimal inventory levels, reduced storage costs, and fewer stockouts or overstock situations. AI also enhances logistics by identifying the most efficient delivery routes and reducing transportation delays.

Streamlining Workflows and Decision-Making

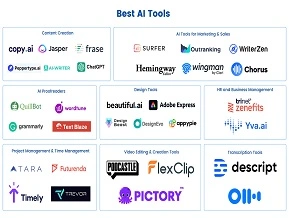

AI-powered tools are revolutionizing workflows by automating routine decisions and providing actionable insights. From production planning to quality control, AI can analyse vast datasets and recommend the best course of action in seconds. This speeds up decision-making and reduces human error. Workflow automation tools powered by AI also ensure that processes are executed consistently and efficiently, freeing up human workers for more strategic tasks. it plays a critical role in enhancing productivity by making operations smarter, faster, and more responsive. Businesses that integrate AI into their core functions are better equipped to thrive in today’s competitive industrial landscape.

How is AI Driving Profitability in Industrial Applications?

It is not just about innovation—it’s a key driver of profitability. By cutting costs, improving quality, and enabling smarter decision-making, AI helps industrial businesses stay competitive and financially strong.

Cost Savings Through Automation and Efficiency

One of the biggest financial advantages of AI in industrial applications is automation. AI-powered machines and software can take over repetitive, time-consuming tasks such as quality checks, scheduling, and equipment monitoring. This reduces the need for manual labour, lowers operational costs, and minimizes errors. Additionally, AI improves energy efficiency by optimizing resource usage, which can lead to significant long-term savings.

Enhancing Product Quality and Customer Satisfaction

AI also plays a vital role in improving product quality. Machine learning algorithms can detect defects, monitor consistency, and ensure that products meet strict quality standards in real time. This level of precision reduces waste, enhances brand reputation, and leads to fewer returns or complaints. High-quality products naturally result in higher customer satisfaction and retention, which directly contributes to revenue growth.

Data-Driven Forecasting and Strategic Planning

Another way AI boosts profitability is through its powerful data analysis capabilities. By collecting and analysing data from production lines, customer behaviour, and market trends, AI helps businesses make informed decisions. Accurate forecasting of demand, production needs, and maintenance schedules enables better resource planning and reduces unexpected costs. Strategic planning becomes more effective when it is based on real-time, data-driven insights.

It is a valuable asset for driving profitability. It helps businesses reduce expenses, deliver higher-quality products, and make smarter decisions that lead to long-term success in a competitive market. As AI continues to evolve, its role in shaping profitable industrial operations will only grow stronger.

What are the Real-World Examples of Artificial Intelligence in Industries?

It is not just a concept—it's already being implemented across various sectors with transformative results. From automotive production lines to energy management systems, AI is driving innovation, efficiency, and profitability. Below are real-world examples showcasing how AI is reshaping different industries.

AI in Automotive Manufacturing (Tesla, BMW)

Automotive giants like Tesla and BMW are leveraging AI to revolutionize manufacturing processes. Tesla uses AI-powered robots and computer vision for precise assembly and quality control, reducing defects and speeding up production. BMW integrates AI into its production system to detect errors in real-time and automate logistics inside factories. These innovations result in faster production cycles, reduced downtime, and higher product quality.

AI in Food Processing and Packaging

In the food industry, AI is streamlining processing and packaging operations. For example, food companies use AI-driven vision systems to inspect products for quality and consistency. AI can detect contaminants, sort products by size or ripeness, and ensure correct labelling and packaging. This not only improves food safety but also enhances operational speed and reduces waste. AI also helps forecast demand and manage inventory more effectively, reducing spoilage and improving supply chain efficiency.

AI in Energy and Utilities

AI is playing a key role in transforming the energy sector. Utilities companies use AI to predict energy demand, detect faults in the grid, and manage renewable energy sources like solar and wind. For instance, AI algorithms can forecast weather conditions and adjust energy distribution accordingly. This optimizes energy usage, lowers costs, and supports sustainability goals.

These examples illustrate how Artificial Intelligence in Industries is being applied in practical, high-impact ways—transforming operations, reducing costs, and enhancing performance across sectors.

What are the Challenges and Considerations in Implementing Artificial Intelligence in Industries?

While the benefits of these are clear, implementing AI comes with several challenges and important considerations. From technical hurdles to workforce readiness and ethical responsibilities, businesses must carefully navigate these issues to ensure successful adoption and long-term value.

Integration with Legacy Systems

One major challenge is integrating AI technologies with existing legacy systems. Many industrial facilities still rely on outdated infrastructure that lacks compatibility with modern AI tools. Retrofitting these systems to support AI requires significant investment, technical expertise, and time. In some cases, it may involve overhauling hardware, updating software, or building custom interfaces—all of which can disrupt ongoing operations if not managed properly.

Skill Gaps and Workforce Training

The successful deployment of AI relies on a skilled workforce that understands both the technology and the business processes it affects. However, many industries face a shortage of workers with the necessary AI, data science, and machine learning expertise. Upskilling current employees through training programs and hiring AI specialists are essential steps. At the same time, businesses must address concerns among workers about job displacement by emphasizing the collaborative potential of AI rather than replacing human roles.

Ethical and Data Privacy Concerns

As AI systems collect and process vast amounts of industrial and personal data, ensuring privacy and ethical use becomes critical. Companies must develop policies to protect sensitive information, comply with data protection regulations, and ensure that AI decision-making is transparent and fair. Bias in AI algorithms and the misuse of predictive models can lead to unintended consequences, including reputational damage or legal issues.

In conclusion, while it offers tremendous opportunities, companies must tackle integration, workforce, and ethical challenges thoughtfully to maximize benefits and build trust in AI-driven operations.

What Does the Future Hold for Artificial Intelligence in Industries: Trends and Innovations?

As industries continue to evolve, Artificial Intelligence in Industries is set to play an even more central role. With the rise of smart factories, human-AI collaboration, and cutting-edge innovations, AI is paving the way for the next generation of industrial transformation.

AI and Industry 4.0

Industry 4.0, the fourth industrial revolution, is defined by the fusion of digital technologies with traditional manufacturing. AI is at the heart of this shift, enabling real-time data analysis, autonomous decision-making, and intelligent automation. From self-optimizing production lines to AI-driven supply chains, AI empowers industries to become more responsive, efficient, and adaptive to market demands. As more companies embrace Industry 4.0, AI will become the standard for innovation and competitiveness.

Human-AI Collaboration in Industrial Environments

Rather than replacing humans, AI is increasingly viewed as a collaborator in industrial settings. Human-AI collaboration allows workers to leverage AI tools to enhance productivity, accuracy, and safety. For instance, wearable AI devices can provide technicians with real-time diagnostics during maintenance tasks, while AI-powered dashboards assist managers in making data-driven decisions. This partnership ensures that human expertise is augmented—not replaced—by intelligent machines.

Emerging Innovations in Industrial AI

Several ground-breaking innovations are shaping the future of AI in industrial applications. Generative AI is being explored for design and prototyping, allowing engineers to create multiple design variations based on performance goals. Edge AI is another key development, bringing AI processing closer to the source of data (e.g., sensors on machines), which reduces latency and enhances real-time decision-making in critical processes. These technologies promise to make AI faster, smarter, and more accessible across industrial operations.

In summary, the future of Artificial Intelligence in Industries is dynamic and full of promise. As technology advances, AI will continue to unlock new efficiencies, drive innovation, and reshape the way industries operate worldwide.

Conclusion

Artificial Intelligence in Industries offers long-term value by significantly enhancing both productivity and profitability. Through intelligent automation, real-time data analysis, and improved decision-making, AI helps streamline operations, reduce costs, and deliver higher-quality products. As industries face increasing pressure to innovate and remain agile in a fast-changing market, embracing AI in industries is no longer optional—it’s essential. By adopting AI technologies, businesses position themselves for sustainable growth, operational excellence, and a competitive edge. Moving forward, AI-driven innovation will continue to play a central role in shaping future-ready industrial environments that are smarter, more efficient, and more resilient.